The Apprentice Blog

Follow Nina's journey from the bakery to the Laboratory as MSL's first Measurement Technician Apprentice.

January 2021

Happy New Year Everybody! I hope you all are feeling well rested after the summer break.

I have some really exciting news. After my work placement with the Police Calibration Unit in October, I found out that they were looking to recruit a new calibration technician. I applied for the role and I was successful!! So I’ll be leaving MSL on the 29th January 2021. I’ve fulfilled the purpose of the MSL apprenticeship scheme (early!!) and I’ve learned so much more along the way.

While at MSL one of the things I am most proud of is improving my people skills, particularly with presenting. When the idea of doing a presentation first came up I was very hesitant, but now I am a lot more willing and confident to do so, and I can see the great impact it can have on the audience I am presenting to.

I look forward to where my metrology career will take me, who knows where I will end up in the future. In a few years time it would be really awesome to be working in/towards a more senior metrology/calibration role, considering I would have had a number of years experience in the industry.

I have been very thankful for the opportunities MSL has given to develop my metrological skills and knowledge in industry. I have learned a lot of things I would have never thought I was capable of, and met a lot of awesome people along the way.

I would like to give a big thanks to everyone who has supported me through my journey at MSL, and would particularly like to mention Lenice and Kevin, without them the apprenticeship scheme would not have been possible.

To the next apprentice I say always be willing to learn new things and never be afraid to ask questions, no matter how silly you think they are.

I will never forget my time at MSL, and hope to come back and visit in the future. Below is a photo from my MSL 'graduation'.

Nina

December 2020

Merry Christmas everybody!

Wow, what a year it has been! What have I been up to recently? I am here to give you an update :)

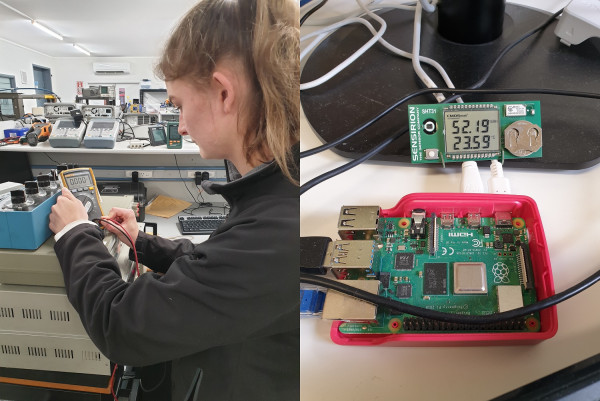

I completed work on my Raspberry Pi project. The outputs of this project were:

- Writing python scripts which completed the following tasks

- Connection to the Wifi

- Connection over Bluetooth to the wireless temperature-humidity sensors

- Logging of data from the sensors into a csv file

- Plotting of the logged data onto a graph which continuously updates as data comes in.

- A project report on how the goals of this project were achieved.

I have also completed a second work placement where I spent a week at the New Zealand Police Calibration Unit in which I got to look at their equipment that they use for catching speed offenders and weighing vehicles to make sure that they are not carrying more load than they’re supposed to.

In October I was given the opportunity present at the House of Science metrology box launch. The House of Science is an organisation which provides lots of different science kits to primary schools around New Zealand. The House of Science's goal is to improve New Zealand’s scientific literacy and ensure that when kids reach high school they don't struggle with the new scientific teachings. In my presentation I talked about how it was a big jump going from primary school where I did not receive a lot of scientific education to high school where we had science taught four times a week.

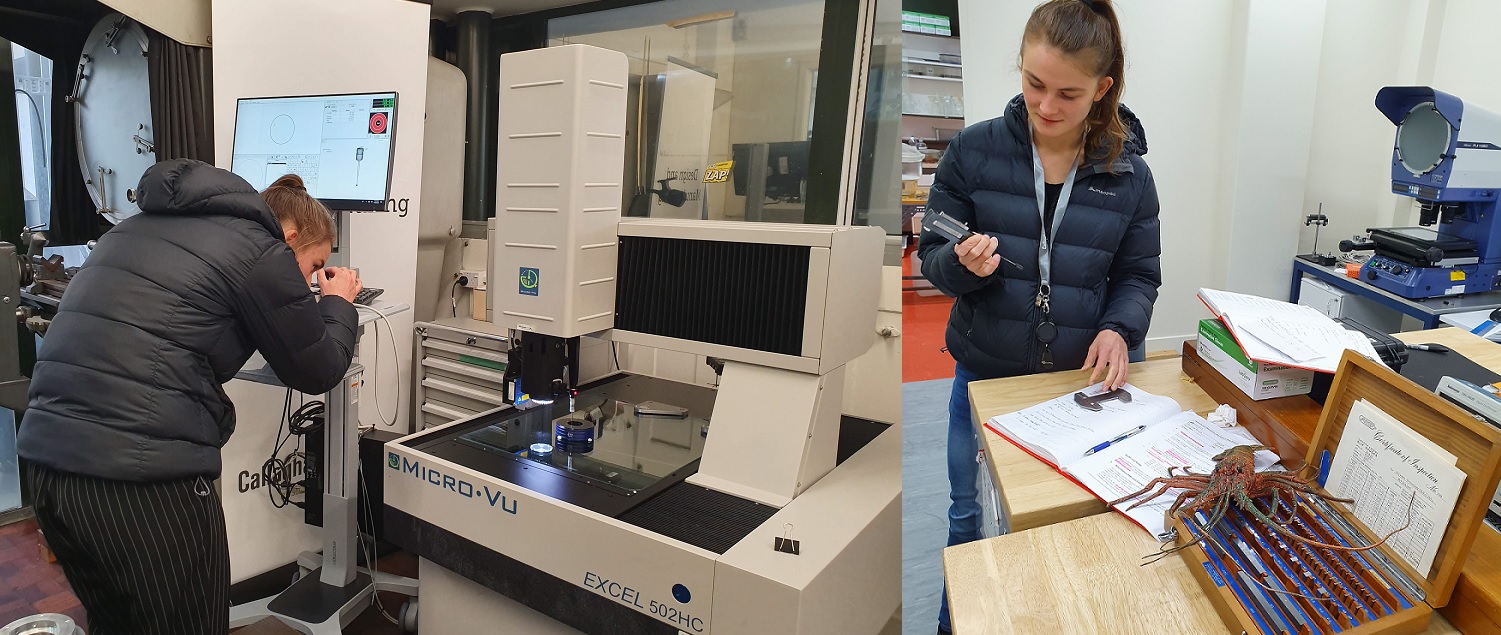

I have been helping with various commercial work such as calibrating tape measures by using a motorised laser, measurement of apertures using a profile projector as well as laser and theodolite measurements.I’ve been working hard to gain a better understanding of programming a small CMM we have on site, although it is tricky as every CMM uses different software, it is really great when you finally programme a part and it works.

I have completed my assignments and exams at Weltec in Material Properties and Manufacturing Processes. It has been challenging balancing working at MSL as well as completing study at Weltec. I am really looking forward to my break over summer.

Earlier this month at MSL I hosted a calibration/repair technician Shai from RF Test Solutions. I showed Shai around the labs at MSL and some of my projects and day to day work. I then went and visited Shai at RF test and she showed me around her day to day work such as the admin of calibrations and repairs as well as doing the hands on repair and calibration work. It was really great to do this apprentice exchange as it is not common to see other young people working in calibration. A story about this has been published on our homepage.

Recently, I have spent some time in MSL's Time and Frequency Labs. This is an area that is completely new to me. I learned a lot from the Time and Frequency team about using an oscilloscope to visualise different frequencies and changing the display based on what measurement is required. I even got to see the atomic clocks that keep the standard time for New Zealand!

Anyways that’s all from me :) I hope everyone has a wonderful Christmas and a Happy New Year!

Nina

1 August 2020

Can you believe it? MSL’s apprentice has been here for over a year now! That time just flew by. Everyone likes to say how quickly time goes by when you’re having fun ;).

It has been really good getting back into the office and the lab over the past couple of months after being away for a while due to Covid-19!

What have I been up to since my last update?

One of the first things I did when I got back to MSL was complete my first apprentice assessment. This assessment entailed a practical and theoretical side. I had to complete and teach the calibration of an external micrometer to a colleague from outside the Length section for the practical assessment. Following the micrometer calibration was the theoretical segment I answered questions around quality, measurement practice and measurement uncertainty. The purpose of this assessment was to give my mentors and myself an idea of where I had got to with my learning, and where we needed to head to from this point onwards.

I’ve finished the statistics paper I was completing at UCOL (Palmerston North). I won't be doing any more UCOL papers as we found it wasn’t quite the right fit for what a metrology apprentice should be learning. Therefore, we needed to find another tertiary provider to help aid my learning and that’s when we started investigating the mechanical engineering programme offered at WELTEC (Wellington). This papers offered in this diploma were better catered to what MSL is trying to achieve in educating a metrology apprentice. So I am taking two papers this semester from the New Zealand Diploma in Engineering.

I have continued to assist my colleagues in commercial and research work. This has entailed helping with the calibration of tape measures and rules, and offering a hand with the analysis of the behaviour of a digital level in which we were looking at the collimation error.

Recently MSL purchased a Raspberry Pi (which is a credit card sized single board computer) and some dual temperature and humidity sensors for me to work with. It has been really interesting and challenging trying to set up the Raspberry Pi and talk to it through another computer, this is because one of the tasks set for me was to setup the Pi without using a GUI (Graphical User Interface), this means there was no monitor, keyboard or mouse to communicate to with the Pi. I have set this up and now I’m focusing on getting the Pi talking to the sensors. This is proving a challenge at the moment, due to it being my first time writing python scripts for a real project. I have learned some python while at MSL, but this will be a huge learning curve in the application of this knowledge.

At World Metrology day I was able to participate in an online panel presentation which was open for anyone to attend. Before the live event on 20th May, most of the presenters created a Youtube video on a certain topic, then at the live panel discussion attendees could ask questions about what was covered in the videos. My YouTube video was on what my experience had been like as MSL’s first apprentice up until that point. I was quite nervous going into the panel discussion as that was probably the largest amount of people I had talked to in my life (even though it was virtual). However, everything went well, so I was relieved.

Lastly, Lenice and I have been preparing for the Micrometer Proficiency Test. Part of this is working on formulating uncertainty budgets, and coming up with model equations for the uncertainties. I have really enjoyed learning this and I can’t wait to do more!

That’s all for now :)

Nina

1 April 2020

Blogdown week one….. Just kidding!

Wow here we all are working from home, it feels like our world has been flipped upside down! To brighten things up a little I thought it was about time for the third edition of the apprenticeship blog!

So, what have I been up to for the beginning months of this year? After a quiet couple of weeks overeating over Christmas and New Year it was time to get back in the lab!

At the end of January I got to go on an amazing trip to Christchurch for three weeks to go and visit Air New Zealand's Calibration lab. This trip was very exciting as I had never been to the South Island before. I tiki toured around the city on weekends and even went and visited Akaroa and Hanmer Springs which was lovely! On the calibration side of things, I was exposed to a completely different environment than what I am used to at MSL.

Air New Zealand is a commercially focused lab and MSL is more research and maintenance (of primary standards) focused. Air New Zealand has a great deal of tools that come in each day for calibration whereas at MSL we get only a few every month. I saw the time constraints the staff had to meet to get a job out the door, each tool had a certain amount of time allocated to it for the calibration and report to be completed. This would be very similar for other calibration labs I would imagine, so it gives me a good idea for what I am getting myself into for the future. What I really enjoyed about going to visit Air New Zealand was that I got to visit other areas of metrology that I am not usually around (I am in the length and dimensional team). I first started off in the dimensional area, but then expanded to pressure, temperature, mass and torque as well which was beneficial for my learning as at MSL we do not do a lot of the calibration work commercial labs do, as we have different focus areas. I also met some awesome people at Air New Zealand which made the trip even better!

In addition to visiting Air New Zealand I have been working on other projects at MSL. One of these projects is on the calibration of Mechanical Length Measuring Instruments such as Calipers, Micrometers and Dial Gauges. The catch with this project is I am also going to be writing my own technical procedures for them too, my mentor Lenice will then check over them and fill in any gaps to better my understanding.

Another project I have been involved in is the reusability of 3D nylon printing powder. The reused powder wasn't running through the 3D printer properly, and it is believed to have been caused by a missing flow agent which has been burnt off in previous printing runs. So, it is my job to test different concentrations of flow agents with the recycled powder to get the right mix, this is still on ongoing project.

Last but not least I have finally started my Biostatistics course at UCOL. I have found this course interesting and really enjoy it as it is something quite different to my everyday work. So far, I have completed one maths test and am working on a microbe enumeration report where I grew E. coli bacteria in a petri dish with some nutrient agar and then counted the number of colonies present in the agar after leaving it overnight. Data was then gathered from how many E. coli colonies there were and now I must analyse the data using statistics and write a report on my findings.

So that's the main highlights from the first part of this year. I hope everybody has a wonderful Easter and is surviving the lockdown. Until next time

Nina :)

10 December 2019

Wow, I've been at MSL six months already, time goes so fast when you're having fun! Here is a little update on what I have been up to for the past couple of months :)

I completed my Measurement Uncertainty Course from NPL :)

Back in October I attended the three day 17025 Quality management course at IANZ in Auckland, this course was very important for me to attend as I am new to working in a laboratory, it showed why things are done the way they are in laboratories and what affect they have in the long run. I took a lot away from this experience and can now apply it to my everyday work.

Some of the exciting calibration work I have been up to recently has been:

- Learning all about calibrating micrometers which is essential for me to learn as I will be assisting Lenice my mentor with a Proficiency Test next year which involves micrometers.

- Another calibration job I assisted on was the calibration of a stage micrometer, which is a lot different from your regular micrometer. A stage micrometer is a glass biology slide with a very small ruler scale printed on it that can only be seen under a microscope, this stage micrometer is then used to calibrate an eyepiece reticle which is used when making measurements with a microscope. When calibrating the stage micrometer we used a profile projector which is like a really huge microscope and a laser to see how far the microscope table was moving in order to see the graduations on the micrometer.

Another exciting piece of equipment I have been playing around with is an Arduino. An Arduino is a small programmable circuit board which you can use to automate simple tasks. Automation is a very relevant skill to have in the metrology and engineering industry as it helps speed up processes and increase productivity which in turn increases profit, so having the skilled personnel to automate such processes is vital to a company's success.

One more fantastic opportunity I have had since my last blog post was getting to talk to a group called Youth Inspire. Youth Inspire is a community run program with the primary focus of getting young people on the right track whether it be finding a job or going into further education, Youth Inspire teaches these young people the necessary skills in order to succeed in their future endeavours, whatever they may be. I got to talk to the group about my apprenticeship scheme and show them some of the awesome things I have been up to, it really got a lot of them thinking of apprenticeship opportunities and a lot of them were interested in what I had been doing and were asking a lot of great questions! I really enjoyed this experience.

14 October 2019

Nina's story recently featured in the Kapiti News.

30 September 2019

Introduction

Hi, my name is Nina and I am MSL’s first apprentice measurement technician. I am really excited about having this awesome opportunity. MSL is very different from both school and my previous job as a baker, but I like the change as I get to learn new skills, and gain knowledge and am challenged every day. One of my favourite things to do at MSL is sit at the lunch table and hear all the discussions going back and forward between the metrologists. They all know so much, and I love learning from them. To keep a record of the things I do during my time here, I’ve decided to keep a blog. Here is my first post.

Day to Day

My work includes lots of practical experience, but I also do courses too. At the moment, I am primarily based in the length team. I recently used a romer arm for the first time – this is a portable coordinate measuring machine (CMM). I measured a unique item for a customer. It was so large in size it was unable to be measured by our standard CMM.

I recently completed my first commercial job, on the measuring of lobster tail gauges for the Ministry of Primary Industries. This measurement was completed with the use of wrung gauge blocks in the form of go and no-go gauges.

I have also worked a little in the temperature team working with thermometers using triple points and silicon baths for probe conditioning. With the light team I’ve looked at photometers which measure light intensity, the strength of electromagnetic radiation in the range from ultraviolet to infrared (including the visible spectrum).

I’ve started helping Lenice, who is my mentor, to measure components for the development of the kibble balance using the CMM, which is to help realise the kilogram in New Zealand following the redefinition in May 2019.

Training

I have attended lots of courses too, including the MSL workshops for Measurement Uncertainty and Geometric Dimensioning and Tolerancing. I have found this to be really useful – it allowed me to apply what I had learned in the workshops to my day to day tasks in the length team, whether that was learning to read technical drawings, or analysing data from measurements I have taken.

And finally, I’ve been working on alot of online metrology courses at Hexagon metrology and UK National Physical Laboratory (NPL). They cover lots of the skills that I’m applying in MSL’s labs and workshops.

- CMM and Arm Fundamental Courses– These helped give me a basic understanding on the operation of these machines before I began to use them.

- Vision Fundamentals – This course was about Vision CMMs which include probes, lasers and vision (in the form of a camera) to take measurements. I found this course particularly helpful as it provided some good pointers for when I was measuring some apertures – these are very fragile parts used in light standards. They could not be measured using a regular probe.

- Geometric Product Specification and Dimensional Measurement - these were through NPL and they provided a good introduction to coordinate metrology, which is essential in length standards, especially with the use of a CMM.

- Measurement Fundamentals Explained and Introduction to Metrology– These two courses provided a good base for what metrology is all about.

- NPL’s Measurement Uncertainty Explained and Uncertainty Budgets (this second one is yet to be completed) - These courses are essential in any field of measurement, because with any measurement you take there is always some uncertainty.

So, as you can tell, I’ve been really busy. But I’m enjoying the experience a lot, and I’m being well supported by all the team at MSL. I’d better get back to the lab. Keep an eye out for my next post!